Another Bone-Headed Blunder by Obama's Car Czar

There's a reason factories stop for regular maintenance.

-

Tools:

In "In Risky Move, GM to Run Plants Around Clock," the Wall Street Journal reports:

KANSAS CITY, Kan.-Starting Jan. 4, General Motors Co. plans to do something unprecedented in the U.S. car industry: It will run its assembly line here around the clock on a permanent basis.

We've spent many years installing computer systems in automobile plants and know from personal experience that auto plants need too much preventive maintenance to operate smoothly around the clock. Three-shift operations are common in other industries and in plants that supply components to auto makers, but not even Toyota runs its auto plants around the clock.

There's a non-obvious cost to running 3 shifts per day - medical and pension costs mean that the company has spent a huge amount per worker before the worker tightens the first nut. It costs so much to have an additional person on the payroll that it's far more efficient to pay 2 hours overtime, incur two sets of health benefit charges, and run two shifts of 10 hours each than to pay 3 workers' worth of benefits. That leaves 4 hours per day for maintenance, which has become the usual pattern.

"Two shifts gives us the flexibility to perform any necessary maintenance on equipment between shifts," said Mike Goss, a spokesman for Toyota's U.S. manufacturing operations.

A few idle hours between shifts also enables a plant to perform cleaning and restocking. A plant's paint shop alone generally requires about four hours of cleaning a day, said Mr. Harbour [editor of the Harbour report], adding that the efficiencies of a third shift can disappear quickly amid slowdowns for such maintenance.

"If running three shifts means you're moving [the line] at only 60% of capacity, then you haven't gained anything," he said.

In this case, GM has to take on 900 more workers in Kansas City, with all the recruitment, training, and transfer costs that implies. The union contract calls for GM to offer these jobs to UAW members who're being laid off at other plants; GM is offering each of the 900 workers $30,000 to make the move for a total up-front cost of $27,000,000.00 of our taxpayer dollars before one single additional hour is even worked.

Cleanliness No Longer Next To Godliness?

One of the trickiest parts of the switch to 3 shifts is figuring out how to clean and maintain the machinery without stopping it. They're looking ways to run parts of the line at "overspeed" so that they can then slow it down briefly for maintenance without backing up the rest of the assembly line.

Most of the equipment was designed around a specific number of cars per hour, however. Trying to run it faster than it was designed to go is generally a recipe for increased wear and more maintenance, not more production.

Assuming all goes well, the line will make 6,300 vehicles per week instead of 4,500. That will in theory benefit the company - but only assuming they can sell the cars. If they don't sell, they'll have to lay off the 900-person 3rd shift which they've assembled at such cost and be back where they started, only poorer and with unduly worn-out machinery.

Why would GM take such a risk before sales pick up? It turns out that the Obama administration task force that took over the company last spring was surprised to find that industry practice was to run auto assembly plants at two shifts about 250 days per year.

The 250 days per year is a result of the many, many holidays and much time off from work which have been negotiated by the unions over the years, but two shift operation is based on extremely practical considerations involving maintenance, repair, and health benefits. The plant could operate more days per year without difficulty, but this would require concessions from the workers.

Instead of using the powers of bankruptcy court to force the workers into a more practical schedule, the Obama task force instead recommended that the company try to operate at 120% of what was considered to be normal capacity by - guess what? - hiring more union workers, which was the object of the exercise all along.

Manufacturing experts are skeptical, noting that the task force has little experience in the auto business, but that's what comes of being owned by an administration that's more concerned with maintaining UAW jobs than with making a profit.

We'll see how this works out. It's barely possible that Obama's government minion has unearthed a massive latent efficiency improvement that has escaped the view of billions of dollars of research and thousands of engineers hoping for a great victory to boost their next promotion, but we wouldn't count on it.

More likely, Mr. Obama is headed for another F on his job-creation score.

-

Tools:

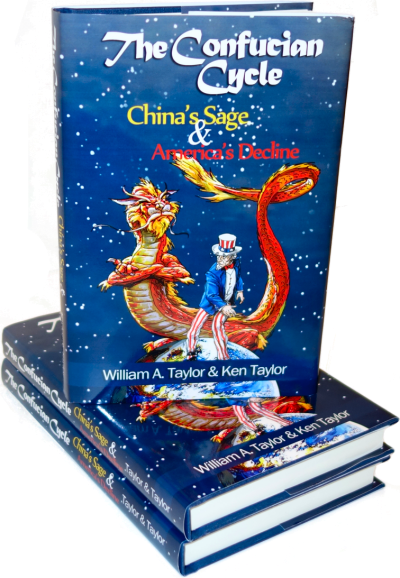

What does Chinese history have to teach America that Mr. Trump's cabinet doesn't know?

"We've spent many years installing computer systems"

Who is we? I didn't realize that Scragged moonlighted as an automotive engineering firm.

In addition to problems of damage to machinery for working too long and too quickly you also have the problem of the workers. Accidents do happen and working faster than is prudent is a good way to get someone hurt. Let us hope they take that into consideration as well.

To your larger point, though - yes, the writers of Scragged do indeed moonlight in various other lines of work, though not currently in automotive engineering.

That's not true anymore. GM hasn't made money in years, and would have died if it wasn't saved by your tax dollars. Why was that done? Yes: to provide union jobs, and for no other reason. It's not like there aren't other places to buy cars.

Besides which, opening a new factory would also create additional union jobs, so if the goal is simply to increase the number of unionized employees where is the benefit with this plan?

There were plenty of other things the government could have "invested" in had saving jobs in general been the goal. They chose instead to save union dinosaurs.

Why then if the idea is to increase the number of union jobs would this be the best option. Let us not also forget that many construction jobs are union so building that new factory would be a great addition.